🔮 The trend is your friend

How can your production team know when tooling is starting to wear down? 🤷♂️ Or recognize when machine performance is starting to fail? 📉 Monitoring process conditions is a key activity for any line operator. But if they can’t see what’s happening, how can they prevent downtime? 🤔

In this Plant Engineering article, condition monitoring is explored. They make the critical point: “trending will provide the operator the time to recognize an issue.. before a flag will be raised with set alarm limits.” Read it here:

“The key is performing the right tests on the right equipment at the right time to predict when maintenance is needed.”

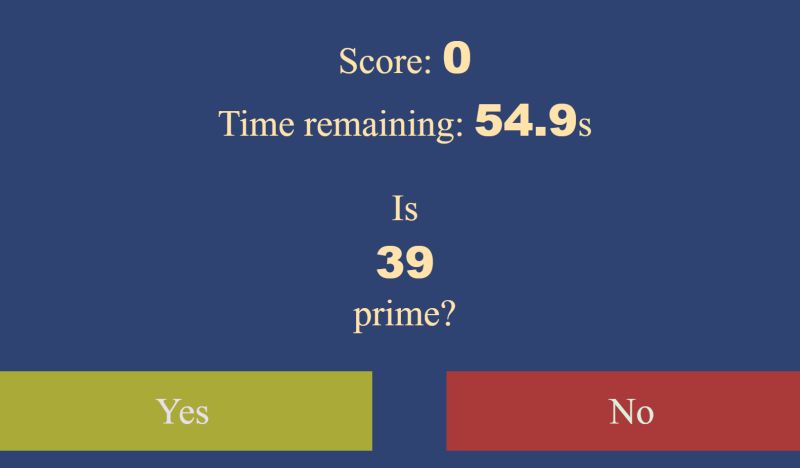

We couldn’t agree more. If your operation is not ready for lots of sensors and IOT, we have an alternative solution for you. Trendable for Data Collection allows operators to manual enter measurements and see trends in real-time. This helps them spot the patterns and make adjustments before a bad part is made! 💥

If you liked this post, sign up to receive our newsletter: