What is Special Cause Variation?

Quality managers need to be aware of the various types of variation that can occur in the manufacturing process. One of the most important of these types is special cause variation, which can have a significant effect on the quality of products.

What is Variation?

Variation is the difference between the expected outcome of a process and its actual outcome. In manufacturing, variation can occur due to a number of factors, including environmental conditions, equipment malfunctions, and human error. Variation can be divided into two categories: common cause variation and special cause variation.

Common Cause Variation

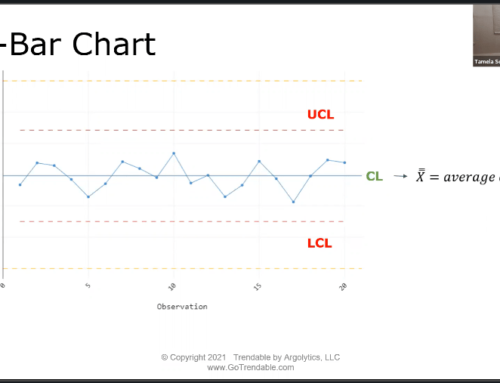

Common cause variation is the result of normal fluctuations in a process. These fluctuations can be expected and do not indicate a problem with the process. Common cause variation can be managed by making small adjustments to the process or by using statistical process control methods.

Special Cause Variation

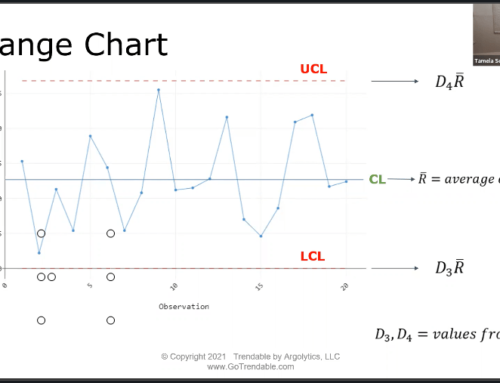

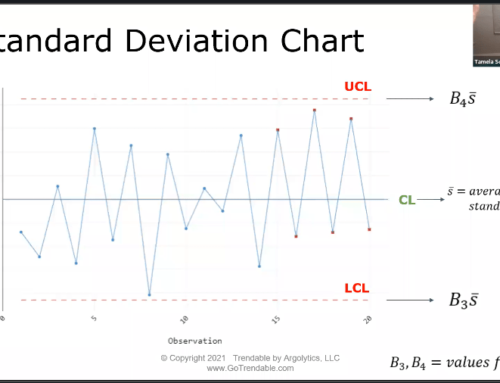

Special cause variation is the result of an unusual event or condition. These events or conditions are outside of the normal range of variation and can indicate a problem with the process. Special cause variation should be identified and addressed quickly, as it can significantly affect the quality of products.

How to Identify Special Cause Variation

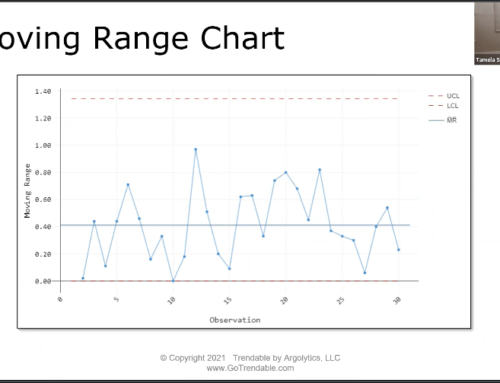

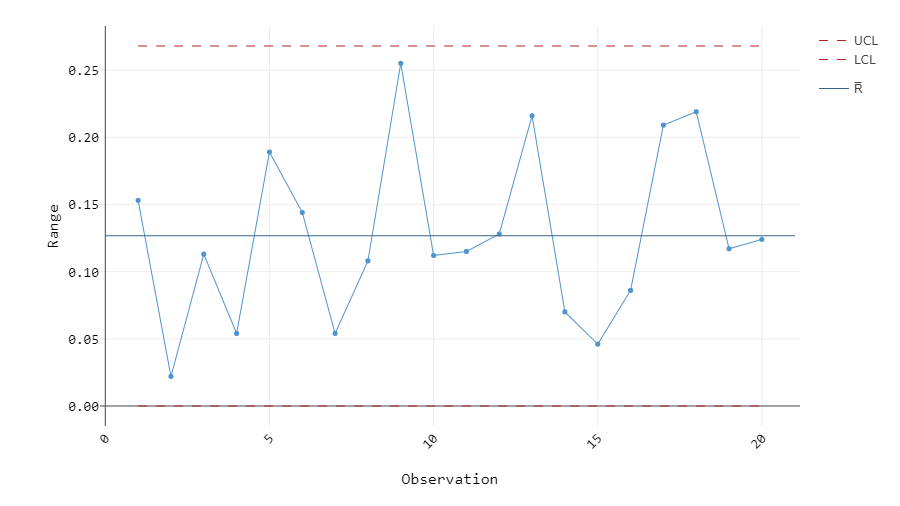

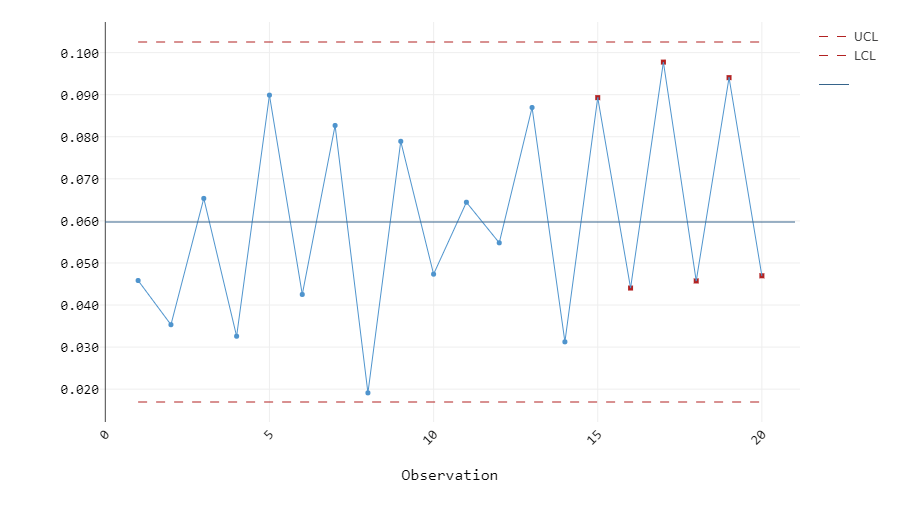

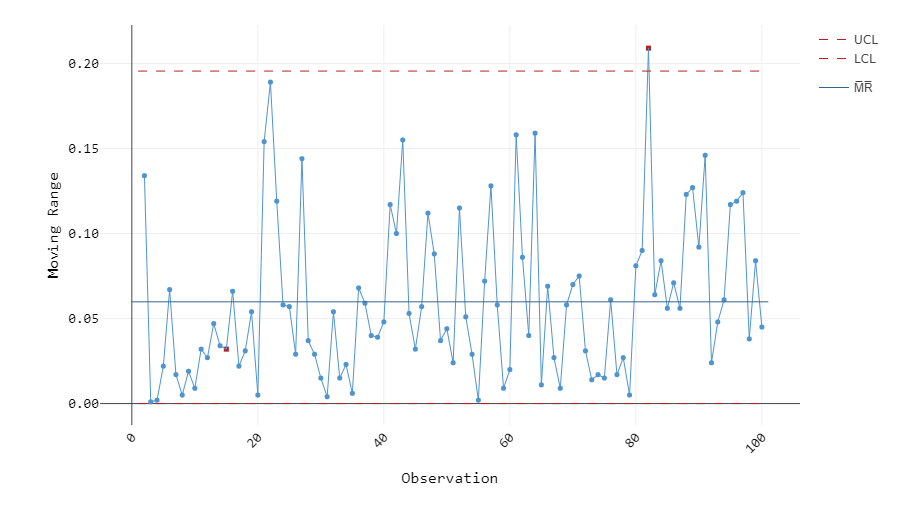

Special cause variation can be identified by using statistical process control methods. These methods involve creating control charts to monitor the process and identify any points that fall outside of the established control limits. The control limits are determined by calculating the standard deviation of the process. Any points that fall outside of the control limits indicate special cause variation and should be investigated.

Steps to Take When Identifying Special Cause Variation

- Identify any points that fall outside of the control limits.

- Investigate the cause of the variation.

- Implement corrective action to address the cause.

- Determine if the corrective action was effective.

- Continue to monitor the process.

Conclusion

Special cause variation can have a significant impact on the quality of products. Quality managers should be aware of the methods used to identify special cause variation and the steps that should be taken to address it. By using these methods, quality managers can ensure that their products meet the highest standards.