🔮 Variation!

How much of your process variation is actually due to measurement variation? 😬

Accuracy and precision are key to the quality of your product. So you inspect and take measurements. But how can you trust that the measuring device you are using is giving you accurate readings?

In this recent article by Modern Machine Shop, a manufacturing operation monitors their gaging to ensure it maintains its performance.

There is a lot of data that needs to be collected on any shop floor. That is why the collection process “must be transparent to the person making the measurement.” 👻

This insight really hit home for us at Argolytics. The biggest new feature in Trendable for Data Collection incorporates gage identification. Allowing our customers to keep track of gage performance over time is key to their success.

🎢 Tangent

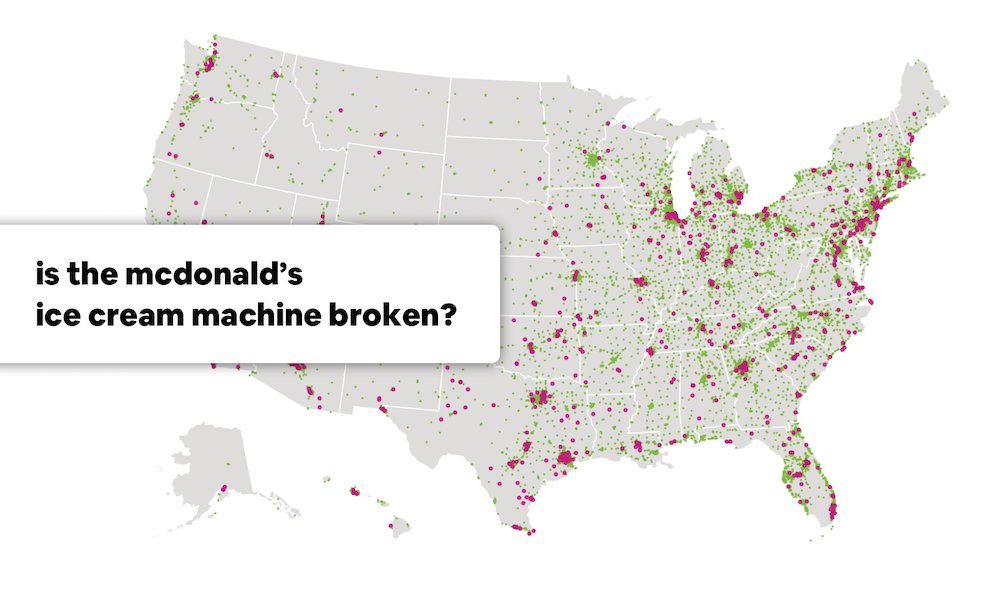

- #Maintenance: McBroken.com maps out all the McDonald’s near you: green if the ice cream machine is working and red if it’s broken.

-

-

-

-

-

- (Or take a trip down the McFlurry rabbit hole)

-

-

-

-

If you liked this post, sign up to receive our newsletter: